Wolfson Tree Management Centre

by Invisible Studio

Client Forestry Commission

Awards ���������� South West Award 2017, ���������� South West Sustainability Award 2017 - , and Stephen Lawrence Prize shortlist and ���������� South West Client of the Year 2017 - , Stephen Lawrence shortlist and ���������� National Award 2017

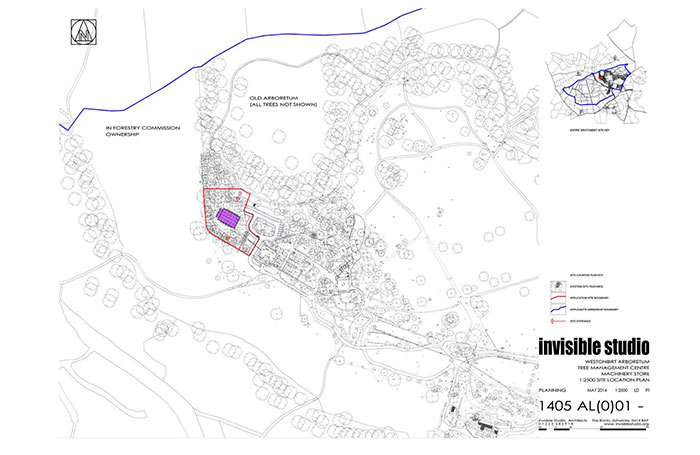

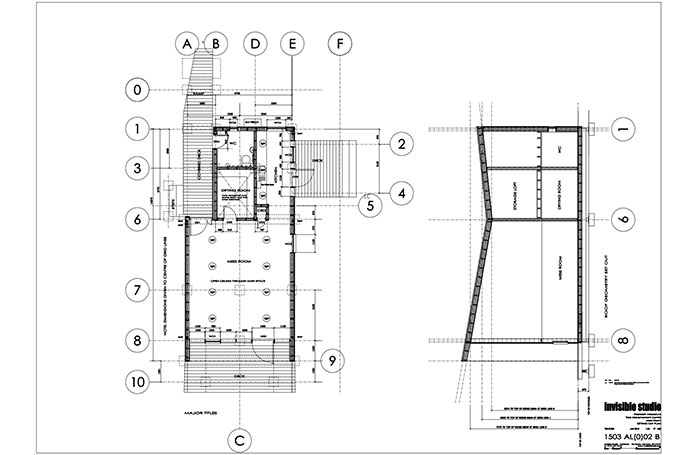

This entry is formed of two timber buildings at the National Arboretum in Gloucestershire. These buildings were built under architect and client supervision by volunteers and trainee carpenters.

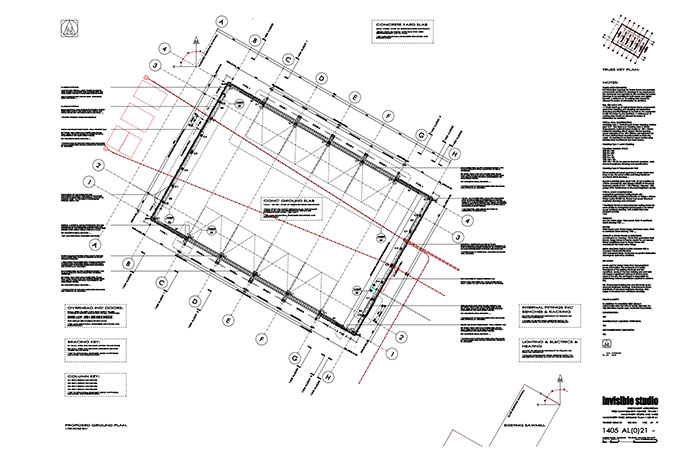

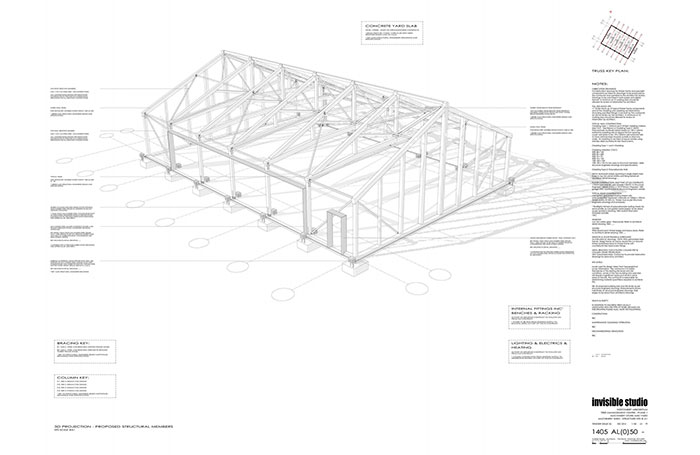

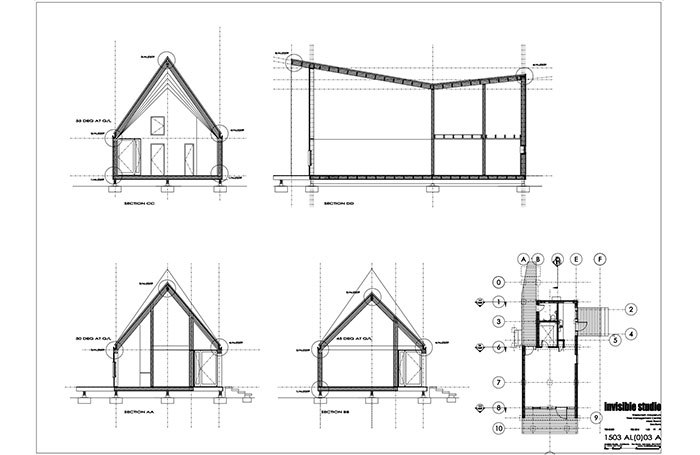

The carbon footprint has been kept to a minimum using locally sourced timber to both form the structure and clad the two buildings. The machine shed, 35 x 20 metre space, is for tractors and agricultural equipment and the mess room for communal staff facilities, including drying room. These two buildings both designed by Piers Taylor focus on the staff requirements for the arboretum. Both buildings are well sited away from the public areas of the site and close to each other.

Seven handmade giant trusses form the roof structure, the bottom string of each truss is fashioned from a single tree, its natural curvature utilised for optimum structural efficiency. These trusses allow for a column free space essential for the easy manoeuvring of tractors and equipment.

The arboretum was first established by Robert Holford in the Victorian era and is now owned and managed by the Forestry Commission with an internationally recognised collection of over 15,000 trees.

We were impressed by subtle but thoughtful decisions such as bending the barn roof of the mess room to allow the morning sun to hit the concrete forecourt of the machine shed to help defrost that surface in the winters morning. A variety of timbers have been used for their strength and reliability; English oak, larch, Corsican pine and douglas fir.

Designed to a tight budget, these buildings demonstrate that with the right design approach, locally sourced materials can be used to reduce the environmental impact of the built environment as well as reducing the construction costs.

Surface water is drained into a soakaway under the machine shed yard, minimizing the input of the additional load on the existing drainage network. A fuel separator ensures that contamination from vehicles does not drain into the soakaway and contaminate the ground. It should be noted that 50% of the cost of the machine shed was in the foundation slab.

The project demonstrated strong client leadership particularly as there were three concurrent projects for this site.

Contractor Carpenter Oak & Woodland / Perchard & Co

Structural Engineer Buro Happold

Internal Area 700 m²