Improving workspace environment for garment factories in Bangladesh: design guidelines for clothing workers’ thermal comfort

Mohataz Hossain, Sheffield Hallam University

Awards ���������� President's Awards for Research 2020

Category Design and Technical

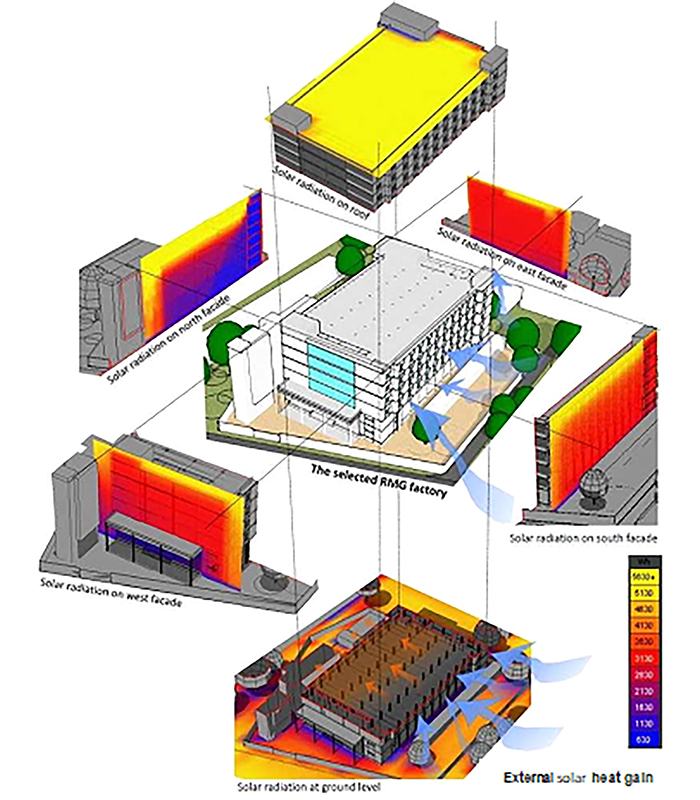

This research aims to identify viable design strategies that can improve the indoor thermal comfort within the workplaces of existing multi-storey ready-made garment (RMG) factories in the tropical climate of Bangladesh. The research framework was initially developed through literature reviews and a feasibility study on the applicability of a passive design approach within an existing RMG factory. The principal research follows the empirical case study approach collecting environmental data for three types of workspaces (i.e. cutting, sewing and finishing sections) and subjective responses from the workers, designer and owners of three multi-storey case study buildings during the three main climatic seasons (i.e. cool-dry, hot-dry and warm-humid seasons) of Bangladesh. In addition to field studies, a validated simulation study is also completed in one of the case study buildings. Analyses of the subjective votes established garment workers’ preferred thermal comfort range for temporal varieties of the climate and suggested that the distance between their workstation and ventilation-inlets should be maintained within 12m to 18m for more personalised control on their comfort avoiding the ceiling fans. Analyses of the environmental data from all case study buildings indicated that the limited effective openings of the existing windows and the ventilation strategy being limited to only occupied hours influence the thermal environment of RMG workspaces. Building owners saw value in implementing two solutions (i.e. altering existing window type to one with a higher effective opening area and utilising a night-time ventilation strategy with thermal mass) immediately in their existing buildings as well as new buildings. Simulation results confirmed that these two interventions can provide reductions of up to 23% of working hours when high temperature is experienced. Moreover, designing stack induced ventilation through shafts and changing functional arrangement can provide additional air speed (increase of up to 0.45 m/s) improving workers’ thermal comfort.